- Tech geeks are expected to see a number of industry-first technological innovations

Prior to the HONOR Magic4 Pro’s launch in Malaysia and other countries, HONOR has taken a progressive approach to reveal its HONOR Intelligent Manufacturing Industrial Park to the public, which includes the manufacturing line for the upcoming HONOR Magic4 Pro. According to an interview with HONOR Global CEO George Zhao and information gathered on the scene, the various production procedures and HONOR Magic4 Pro’s unique technology should be visible in broad daylight.

The HONOR Intelligent Manufacturing Industrial Park, located in Shenzhen, China, focuses on manufacturing premium smartphones such as the HONOR Magic and Number series, the foldable screen HONOR Magic V and the upcoming HONOR Magic4 Pro in Malaysia. The cutting-edge park encompasses centers for new product verification, mass production of high-end flagship mobile phones, process and technology development, and smart capacity manufacturing. HONOR aims to bring high-quality products into the world with its chain partners for the ultimate user experience.

HONOR looks at itself as a production company aiming at the highest quality. “In order to achieve a continuous improvement of consumer experience, we aim to break the original comfort zone and challenge ourselves in higher fields. Obtaining an intelligent manufacturing factory is a breakthrough for us in the manufacturing field. Through R&D, trials in mass production and testing, we look in providing innovative products of high quality to consumers,” George Zhao said.

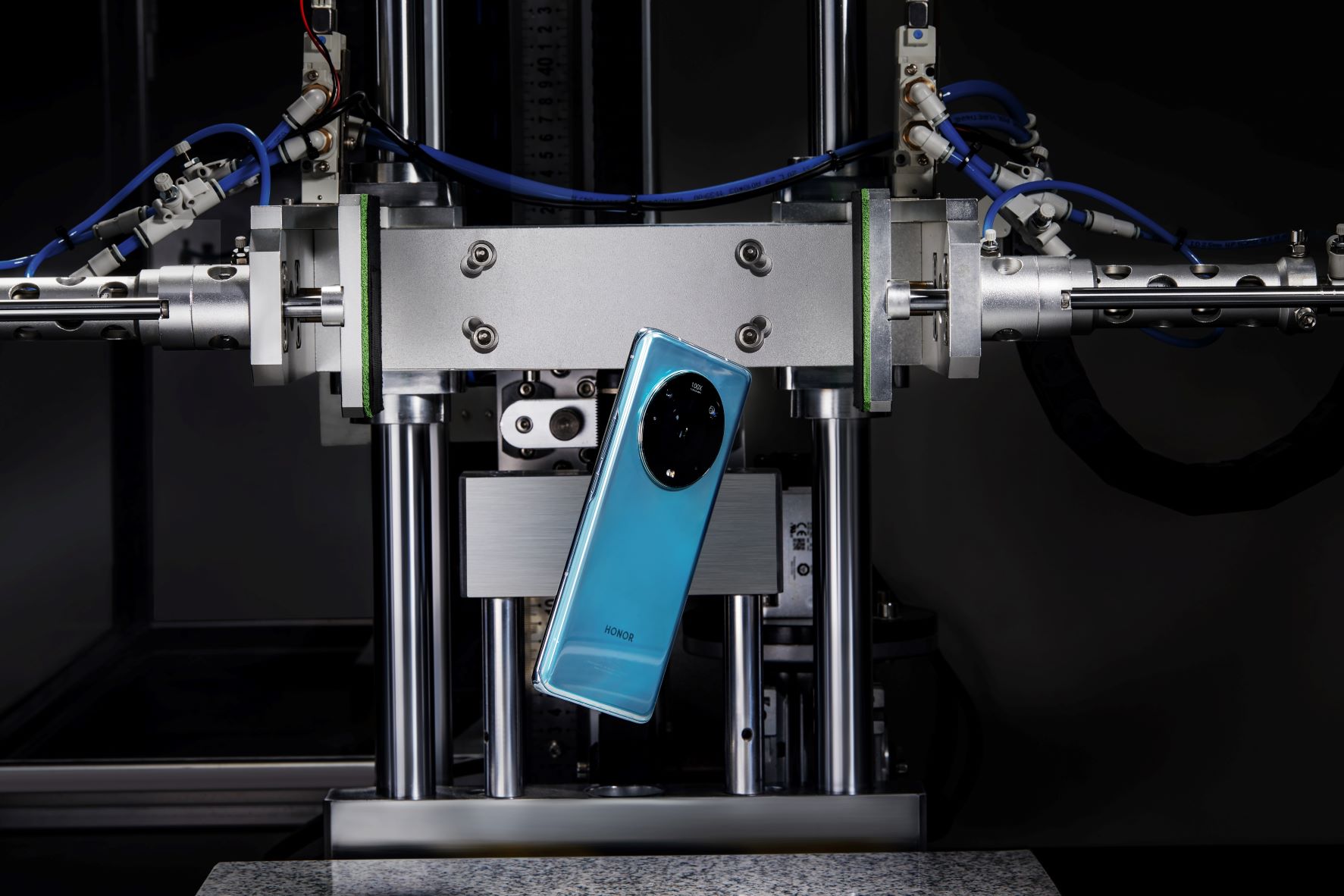

Calibration and automated testing equipment – Ultra-Fusion Photography

The HONOR Magic4 Pro has extended from its predecessors by calibration improvements to attain an extensive level of ultra-fusion photography. For detailed images with authentic colours, the cameras have been integrated with AI algorithms. Thanks to these analyses, fully automated equipment testing were conducted across 100 tests of full focal length range, using a digital platform to collect data with over 300 parameters in real-time to ensure consistency and quality of user experience.

Industry-first Intelligent Dual Sound-Emitting Unit – AI Privacy Call

It comes with the industry’s first AI Privacy Call feature, which is embedded in the HONOR Magic4 Pro, and offers an efficient solution to common sound leakage complaints in smartphones. The feature uses HONOR’s industry-first Intelligent Dual Sound-Emitting Unit, which requires the use of a special bone conduction piece.

The mounting of the bone conduction piece to the screen needs extreme precision, as even minor errors can lead the screen to fail. The R&D and manufacturing teams worked for three months to perfect the automated high-precision mounting equipment, which used computer vision and improved algorithms to reach an accuracy of 0.01mm and a 99.99 % rate.

Automated testing system – Lower Specific Absorption Rate

To ensure product safety, HONOR uses a fully automated Specific Absorption Rate testing system, which compares each of its smartphones to the highest industry standards. The HONOR Magic4 Pro has a required SAR value that is 56% lower than the toughest international standards, according to data from our quality laboratory.

Exclusive Screen Assembly Processes – 3D Quad-Curved LTPO Display

HONOR’s mounting process has an accuracy range of 0.075mm, providing a manufacturing tolerance of 0.1mm, thanks to its six-axis robotic arms, high-precision cameras, and self-developed computer vision algorithms. These figures demonstrate the exceptional manufacturing capabilities of HONOR.

To get updates about the arrival of the HONOR Magic4 Pro to Malaysia, visit HONOR Malaysia official website and click “Notify Me” to subscribe to the latest news here at: https://www.hihonor.com/my/offer/activity/